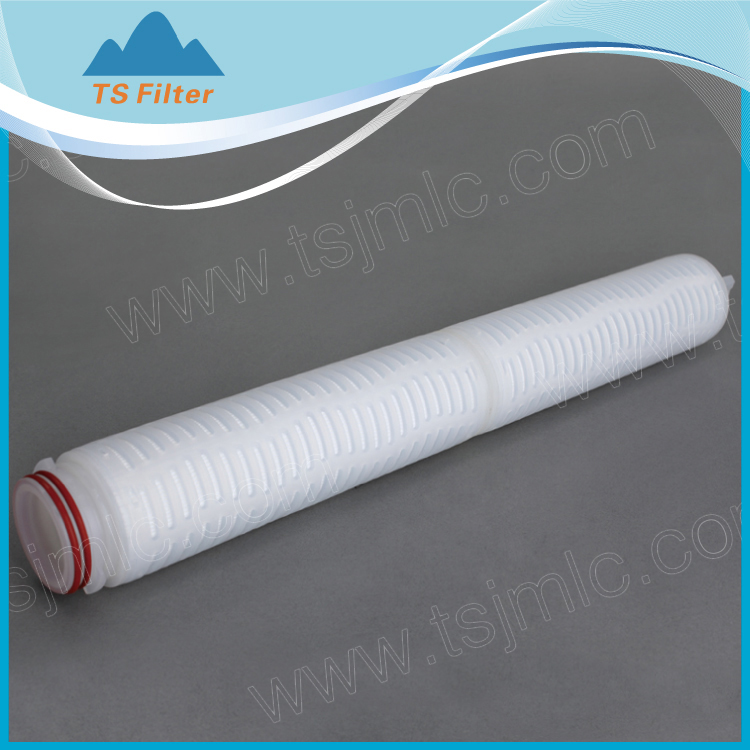

Best quality Approved Hydrophilic PVDF Micron Pleated Cartridge Filters 0.22 Micron/0.45 Micron, Code 7/Code 3 connection

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth “unification, determination, tolerance” for Best quality Approved Hydrophilic PVDF Micron Pleated Cartridge Filters 0.22 Micron/0.45 Micron, Code 7/Code 3 connection, Any requires from you will be paid with our best attention!

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth “unification, determination, tolerance” for TS Made high quality Hydrophilic PVDF filter cartridge, In order to make more people know our goods and to enlarge our market, now we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

◆Hydrophilic PVDF Membrane filter for liquids sterile filtration, Absolute rating ≥99.99%

◆Low protein binding and low extractables, ideal for bioburden reduction and particle removal

◆High throughput flow rate with minimal differential pressure

◆Broad chemical compatibility, suitable for aggressive liquids and high viscosity liquids

◆Withstand multiple steam sterilization

◆Replace Sartorius ,Pall or Millipore Filter is available

•Ophthalmics, WFl;

•Diagnostics, diluents, serum, tissue culture media and media additives;

•Sterile filtration of high viscosity liquid

•Strong alkaline, acids and corrosive solvents;

Table : Typical water flow rate (10″)

| Materials Of Construction | Filter Media: | Hydrophilic PVDF Membrane | ||||

| Support Layers: | Polypropylene | |||||

| Micron Rating: | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um | |||||

| Inner core: | Reinforced Polypropylene | |||||

| Outer Cage, End caps: | Reinforced Polypropylene | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, Teflon, etc | |||||

| Cartridge Dimensions | Outer Diameter | 69mm(2.75”) | ||||

| Inner Diameter | 33mm(1.30”) | |||||

| Length(based on DOE end caps) | 10″- 254mm, 20″- 508mm, 30″-762 mm, 40″- 1016mm | |||||

| Filtration Area(m2) | 0.65 m2 per 10” | |||||

| Operating conditions | Normal Operating Temperature: | Up to 65℃ (140℉) | ||||

| Max.Operating Temperature.: | 90℃ (194℉) at △P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: | Steam Sterilization for 30 minutes at 135℃(275℉) Cumulative Time: 50hours |

|||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10″ | |||||

| GRADE | PRODUCT | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| F - FOOD & BEVERAGE | DHPV | 020-0.2um | AA- DOE | 10-10″ | S-silicone; N-nitrile | |

| P - PHARMACEUTICAL | 045-0.45um | CN-226/FIN | 20-20″ | E-epdm ; T-teflon (encaptulated) | ||

| C - CHEMICAL | 080-0.8um | BN-222/FIN | 30-30″ | V-viton | ||

| E - ELECTRICAL | 100-1.0um | BF-222/ FLAT SEAL | 40-40″ | How to Order?- Example | ||

| CF-226/FLAT SEAL | 05-5″ | Pharmaceutical grade; Micron:0.45um; Length:10″ ADAPTER: DOE; Gakset: Silicone. Selection Code is: PDHPV045AA10S | ||||

| EN-222 three locking ears /Fin | Other-XX | |||||

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth “unification, determination, tolerance” for Best quality Approved Hydrophilic PVDF Micron Pleated Cartridge Filters 0.22 Micron/0.45 Micron, Code 7/Code 3 connection, Any requires from you will be paid with our best attention!

TS Made high quality Hydrophilic PVDF filter cartridge, In order to make more people know our goods and to enlarge our market, now we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.